Crimp terminals

Crimp terminals ensure a safe electrical connection between a cable and a connection piece. They are also used to connect two power cables. Crimp terminals are popular in electrical engineering, automotive and industrial environments, among others. WKK supplies various types, sizes and colors of crimp terminals. We also sell various crimp terminal accessories, such as crimp terminal assortments and crimp tools.

When to use a crimp terminal?

You use crimp terminals when you want to safely connect or disconnect cables to electrical appliances, power or control panels, junction boxes or machines. In addition, they are also used to merge power cables. The product protects devices, cables and people. In most cases, crimp terminals are used for temporary connections, which are easy to disconnect or replace. Permanent installations are also possible but less common.

How does a crimp terminal work?

Crimp terminals offer one of the safest and most commonly used methods for ‘closing’ cables. The product is developed to make cable termination and removal for maintenance or repair very easy.

The electrical cable transfers electrical power to, for example, an electrical device or control panel. The crimp terminal ensures a secure connection. It is important that the cable size and electrical capacity of the connector are correct. If the connection or current capacity is incorrect, a short circuit or a leak may occur. This may result in damage to a machine, device or even endanger the technician.

Crimp terminals and bootlace ferrules are not the same. In principle, both product groups have the same global goals (protection and guidance). However, the applications are different. A crimp terminal connects cables to other cables or devices in order to safely extend the electrical connection between various ends. A bootlace ferrule, on the other hand, is used for cables that reach a final destination (screw terminals, such as a terminal block or automatic circuit breaker). In addition, the connector of a bootlace ferrule is crimped, in case of a crimp terminal it is the insulation sleeve.

Different types: uninsulated and insulated crimp terminals

WKK supplies different types of crimp terminals: uninsulated and insulated. In a limited environment or in a system where cables are close together, you should use insulated crimp terminals. Otherwise there is a risk of a short circuit between the cables.

Uninsulated crimp terminals are used for locations where there is a lot of space or when a large ‘area’ needs to be supplied with electricity or an electrical signal. Uninsulated crimp terminals are a cheaper solution than insulated variants. You can also insulate uninsulated crimp terminals afterwards (watertight) with heat shrink tubing.

Material of the connector

A crimp terminal has a connector with an optional (full) insulation piece. WKK supplies connectors in copper and brass. The insulation material consists of PVC, nylon or polyolefin.

The connector material selection depends on your specific application. Copper, for example, is a better electrical conductor than brass. Brass, on the other hand, is more resistant to corrosion than copper.

Insulation options

PVC insulated crimp terminals are the most common and protect against short circuits. The PVC and the copper connector are shrunk to make the connection to a wire.

The nylon insulated option is shrunk on the wire and on the wire insulation. This results in an improved pull-out strength of the crimp terminal. This variant is ideal for heavy industrial applications, because the shrinkage ensures extra protection.

The polyolefin insulated variant uses plastic and adhesive which insulates the connection. After shrinking or soldering the connection, a heat gun is used to shrink the insulation around the wire. The adhesive provides a water-tight and moisture-tight seal. This method is ideal for applications where dust and moisture can endanger the connection.

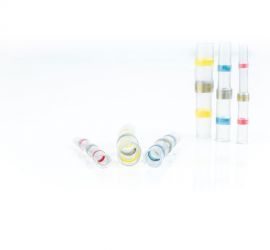

Colors and sizes

The WKK assortment consists of three colors that correspond to a certain size. You will also find the colors on the crimp tools. WKK supplies crimp tools in the colors:

- Red: wire range 0.5 ~ 1.5 mm2, AWG 22 ~ 16

- Blue: wire range 1.5 ~ 2.5 mm2, AWG 16 ~ 14

- Yellow: wire range 4.0 ~ 6.0 mm2, AWG 12 ~ 10

Useful crimp terminal accessories

In addition to the main product, WKK also supplies various useful accessories. You can think of crimp tools for crimp terminals and crimp terminal assortments. We also sell quick splice connectors and fuseholders.

Highlighted types and applications

Frequently sold crimp terminal types are ring, spade and pin terminals. Below you will find the most commonly used application per type:

Ring terminals and spade terminals are often used with a screw (e.g. on a battery). Ring terminals are often used in the automotive industry and are ideal for connecting a mechanical relay or for connecting contactors to engines or other car circuits. A spade terminal is ideal for applications where the ring does not fit around the screw due to an obstacle. A pin terminal is used for applications with a plug connection.

How to install a crimp terminal with a crimp tool

With the help of a special crimp tool for crimp terminals, a crimp terminal is shrunk on a cable. The installation of an insulated crimp terminal consists of the following phases:

- Start stripping the wire. Strip about 7 mm. Use a good wire stripper for this. Work carefully so you do not damage the wires and the cable. Do not twist the released wires around each other, as this may change the wire's diameter and leads to a not reliable connection with the terminal

- Attach the crimp terminal. Make sure you insert the wires deep into the sleeve

- After placing the crimp terminal over the wire, you can complete the clamping with the help of the crimp tool. The tool will release the tension when the shrinkage is sufficient

- Check if the crimp terminal fits properly around the cable

- Ready! You can now connect the product to the intended device

Note: before you start installing a crimp terminal, it is important to ensure clean components. You can clean the conductors with the help of a brush. Make sure that no metal marks are left on the conductor. This can cause contact corrosion.

Soldering crimp terminals (installation without tools)

A second option for installing a crimp terminal is by soldering. Soldering works as follows:

- Strip the wire about 7 mm. Make sure you have a good wire stripper and do not twist the wires around each other

- Then remove the PVC sheath from the crimp terminal. Slip the sheath around the cable so you can slide it into place later in the process

- Attach the crimp terminal to the stripped part of the cable. Use a normal tool to squeeze the connection in the right place. Be careful not to squeeze it too far, otherwise the PVC sheath will not fit properly

- Then let the connection rest on a hot soldering iron for a short period so that it warms up. Now apply a bit of solder to the connector and the wire strands so that the solder can melt completely. Remove the connector in time to avoid lumps of solder

- When it has cooled down, you can slide the PVC sheath back into place

- Ready! You can now connect the product to your intended application

The choice for an installing technique usually depends on your own preference. Some professionals like to work with a crimp tool, others prefer soldering. The tool method is preferred if time and quantity are important factors. When you choose soldering, the quality depends on your personal competence.

Want to know more?

Do you want to know more about crimp terminals? Or do you have other questions? Then contact our advisers. We are happy to help and think along with you about selecting the correct products.